AiQum

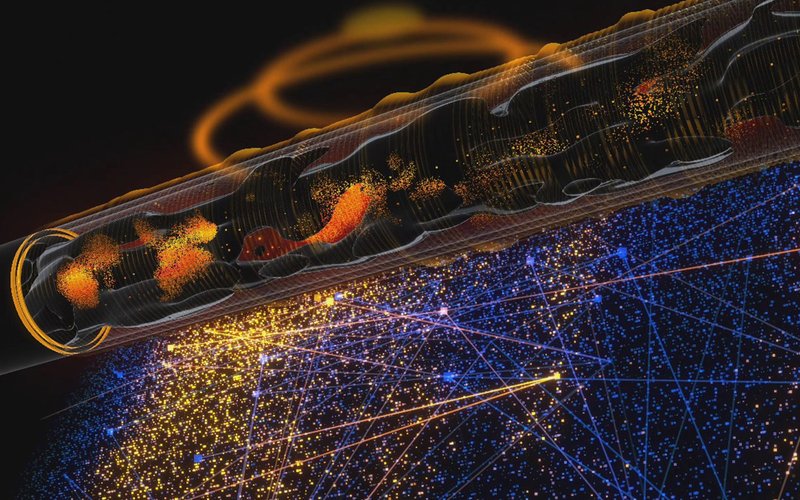

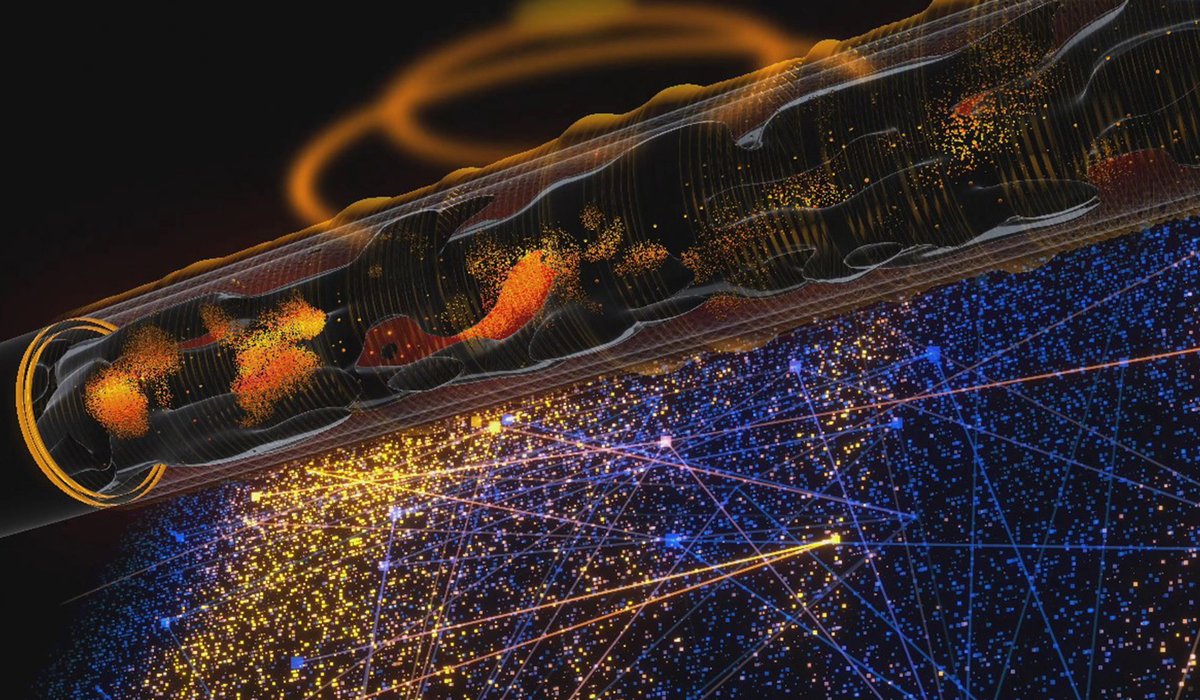

Sand Production Detection

In the Oil and Gas sector, maintaining operational efficiency, asset integrity, and safety is crucial. However, a persistent challenge is sand production, where fine particles migrating with fluids can damage equipment, causing erosion, decreased productivity, and costly downtimes. Effectively managing this issue is vital for the long-term reliability of assets in the ever-changing Oil and Gas industry.

https://researchlab.digital/aiqum

Client: drl-logo-300x193

Date: December 2025

Sector: Energy (Oil & Gas)